Iharanikkei's Strengths

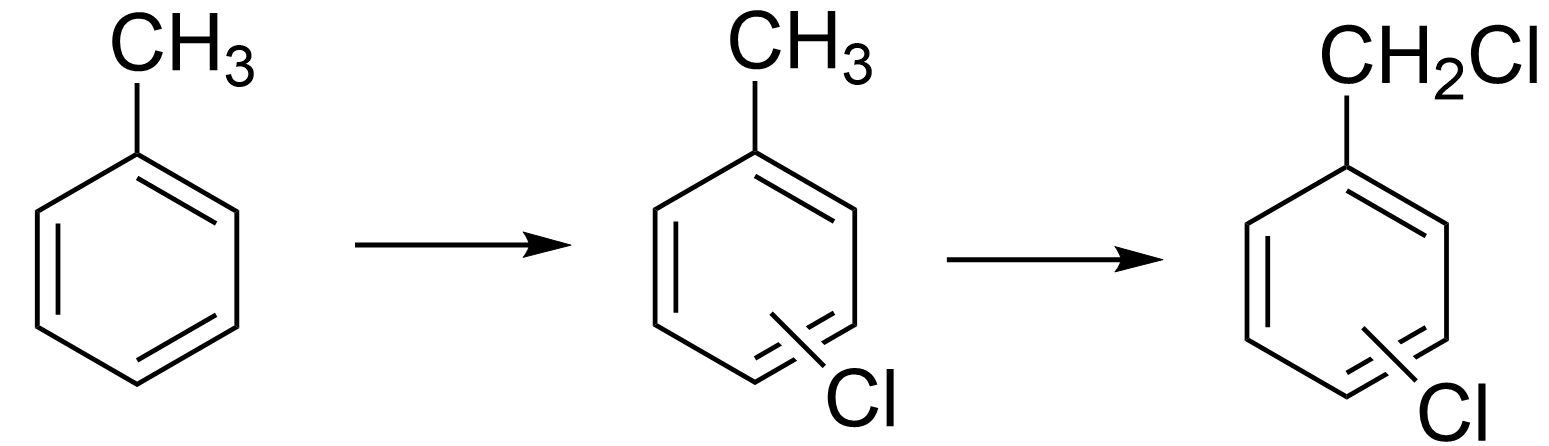

We supply mainly chemical products derived from the Chlorination of toluene and xylene as raw materials for pharmaceuticals, agrochemicals, dyes, resins, and textiles.

Chlorination Technology

| What is Chlorination?"Chlorination" is a chemical reaction in which a chemical substance is given a chlorine atom (Cl). By adding chlorine atoms, reactivity with other substances is improved. As a high value-added fine chemical product, chlorination serves as a raw material for a variety of products.

|

Based on the toluene chlorination developed since the company's founding, we are now focusing on the xylene chlorination and derivatives business.

| We are promoting technological development centered on "Photochlorination Technology," which is one of the few such technologies in Japan that uses light.

| We also respond to customer needs with our expertise in various other reactions. Click here for details of various reaction technologies.

|

Purification technology by distillation and crystallization

| We have a distillation column with a maximum theoretical number of 300 stages, which enables us to separate and purify compounds with extremely small differences in boiling points. Additionally we have several other distillation facilities with 20 to 40 theoretical stages. Furthermore we have crystallization facilities, making it possible to purify compounds that are difficult to purify by distillation. These facilities, combined with our advanced refining technology, enable us to produce highly functional and high-purity chemicals. |

Centralized control system for product management

| We manage our production with a system that we have created through a series of improvements and refinements since our founding. Generally, each plant facility has its own control room, but we have consolidated our production control rooms into a single location. The control system has also been gradually digitized. Excellent plant operators operate and manage the system 24 hours a day. This enables prompt sharing of information and multiple people to check the work status, thereby preventing problems before they occur. This management system is also useful for human resource development. In 1996, we obtained ISO9002 certification, and in 2003, we shifted to ISO9001 certification. Furthermore, in 2002, we obtained "ISO 14001" certification, and our elite technical staff is taking all possible measures to ensure quality control. |

Quality control to maintain high quality

In order to maintain high quality, we have a variety of analyzers to control quality.

|

|

|

|

Chlorine and Hydrogen chloride in large quantities and at low cost

Our plant is adjacent to the Kambara Complex of Nippon Light Metal Co.,Ltd. and both plants are connected by pipeline.Nippon Light Metal Co.,Ltd. manufactures and develops Caustic soda, Chlorine, and Hydrogen by Chloro‐alkali electrolysis, as well as secondary products made from these products.

Hydrochloric acid recovery and refining facility | We consumes some of the Chlorine, and Hydrogen chloride, a byproduct of Chlorination, is sold as Hydrochloric acid or used partially in reactions. By working together, the two companies have established a clean production system that makes the most efficient use possible of Chlorine, a gift from the Sea. In addition, there are only a few companies in Japan that can use Hydrogen chloride gas in large scale reaction tanks, and Iharanikkei is one of those few. |

Production system with low environmental impact

| We produce our products using efficient manufacturing methods, which means that we produce very little waste. Essentially, the production process produces a variety of by-products, but we have expanded our business by making effective use of these by-products and developing applications as raw materials for agriculture, pharmaceuticals, dyes and pigments, resins, and textiles. We also contribute to reducing the environmental impact of the entire supply chain by using Chlorine produced from renewable energy sources in the Chlorination process. |

Production base in Thailand "Iharanikkei Chemical (Thailand) Co., Ltd."

| In 2016, we established a production base in Thailand to start our global operations. The company produces in a two-plant system and exports to Thailand as well as to Europe, the United States, and Asian countries. We supply Terephthalic chlorides and Isophthalic chlorides, which are raw materials for aramid fibers, to fiber manufacturers and others.

In addition, we have launched Chemical Toll Manufacturing Services (OEM), including polymerization reactions utilizing organochlorine compounds. If you are looking for a reliable manufacturing partner in Thailand, please feel free to contact us. |

|  |  |